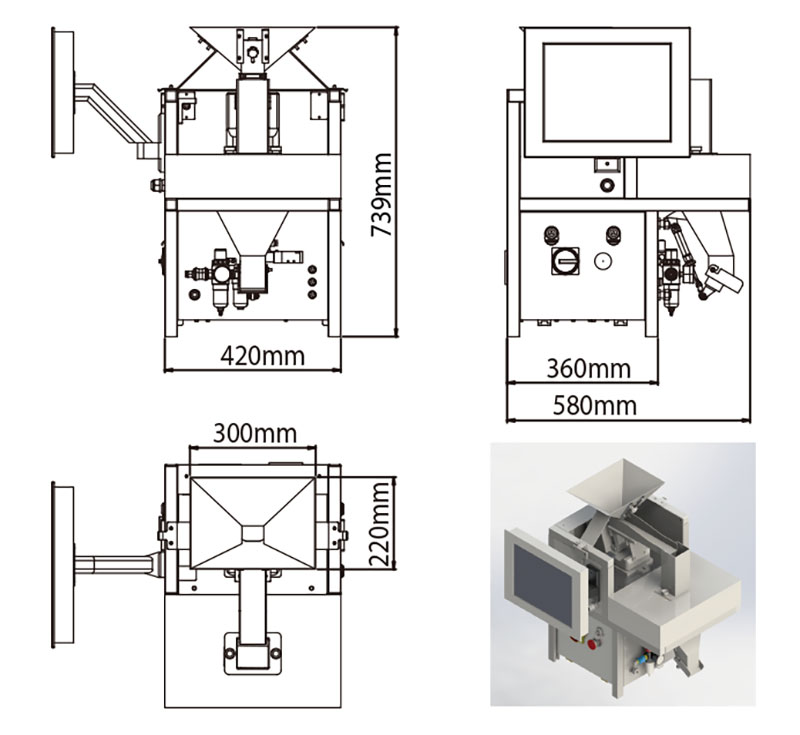

VB82 High speed seed vision based bulk counting & packing machine can count seed for batch package at large production capacity.It is highly accurate by adopting high speed CCD image technology, while counting by weigher is not precise for weight of each seed is not exactly the same.

IPv6 network supported

IPv6 network supported