VB82 Button vision counting & packing machine can count buttons for batch package. It is highly accurate by adopting high speed CCD image technology, while counting by weigher is not precise for weight of each button is not exactly the same

VB500 pet food vision counting & packing machine can count capacitor for batch package. It is highly accurate by adopting high speed CCD image technology, while counting by weigher is not precise for weight of each item is not exactly the same.

Brand:

ZWItem NO.:

VB500Payment:

TT LCProduct Origin:

ChinaShipping Port:

ShanghaiLead Time:

3-6 weeksPet food vision counting & packing machine can count capacitor for batch package by adopting high speed CCD image technology. Advantage of vision based bulk counting machine is precise and efficient to save cost by eliminating the imprecision of most current weighing solutions and reducing labor force.

Working principle of pet food vision counting machine

High speed CCD camera scans objects that fall from vibrating chutes to obtain full projection images through optimized algorithm,machine will count number of falling objects so as to realize the batch counting and packaging.

Technical Characteristics and Specification

1. High speed array camera(10000 times/s scan speed,can realize continuous uninterrupted scanning)scanning imaging,accurate identification count.Avoid counting errors caused by the weight difference of a single material.

2. Coarse control panel + refined panel with 2-3 level vibration structure, composition intelligent feeding system to ensure the counting accuracy.

3. Intelligent learning function,reduce the parameter debugging time.

Through the learning mode,the data of various falling posture of the materials are automatically obtained,and the accuracy of the parameters is checked by the verification mode.If there is an error,the parameters can be fine-adjusted manually.

4. One machine can count N kinds of materials,has strong compatibility.

The system can store N kinds of schemes,which can be called directly next time.

5. With the function of one-key cleaning of tailings,there is no worry about mixing.

When replacing materials,you can click to clean the tailings to perform automatic cleaning,or you can set a mandatory cleaning time to avoid artificially shortening the cleaning time and causing the material mixing

6. All production packaging information automatically generates local logs.

Each package of material packaging information is automatically generated and stored in the local log,and can be uploaded to the ERP system,or exported,for easy future tracing.

7. The ERP information cascade,label information and local log can be sent to the information system.

Label information can be transmitted through enterprise management systems such as ERP, and equipment operation status and each package information are available uploaded to ERP and other enterprise management systems.

8. All packaging number has no negative error,exceed the package can enter the return system.

Eliminate the occurrence of customer complaints caused by less material reasons, beyond the value set,the machine can automatically identify and fall to finished conveyor belt,the belt reverses to discharge the excess bag.

9. Intelligent detection alarm

Foreign bodies,lack of material,abnormal packaging machine will issue an alarm prompt.

10. The storage hopper cut-off port is always open to prevent material blockage

The cutting port of the counting machine is always open, after counting the materials that are easy to hook up, they will gradually fall directly into the bag, so it will not be blocked in the storage hopper

More Field of Application of capacitor counting & packaging machine

Technical data

|

Model |

VB224-2 |

VB63-2 |

|

Applicable material size |

Cube:2mm≤L≤30mm Cuboid /cylinder:φ≤20mm,L≤50mm |

Cube:2mm≤L≤20mm Cuboid /cylinder:φ≤15mm,L≤30mm |

|

Counting accuracy |

99.99%,No negative error |

|

|

Unit pack |

≥100 |

≥50 |

|

Counting efficiency |

φ10mm,1000pcs,3-4bags/min |

φ3mm,1000pcs,3bags/min |

|

φ25mm,200pcs,3-4bags/min |

φ15mm,100pcs,2bags/min |

|

|

Type of applicable materials |

Fasteners, connectors, cold pressure terminals, capacitor, zipper, buttons, seeds, medicine, blood collection needles, steel beads, etc |

|

|

Applicable to packaging machine |

Vertical and premade pouch packaging machine |

|

|

Power/gas source |

220V,50HZ/0.5-0.6MPa |

|

|

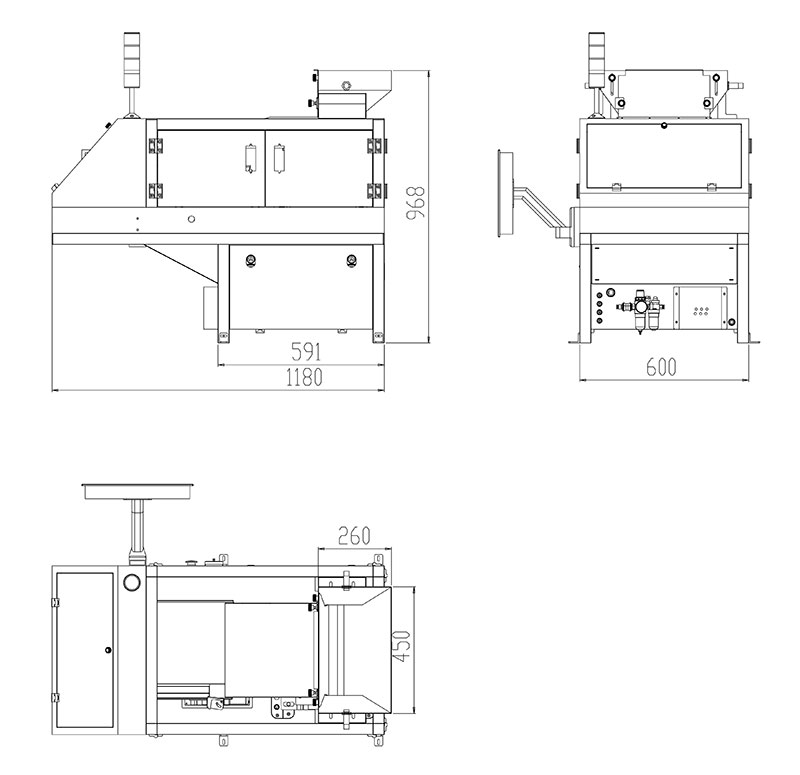

Dimension |

1180mm*600mm*970mm |

940mm*400mm*920mm |

|

Power |

0.4kw |

|

|

Note: The accuracy of 99.99% is based on the measured results of 5mm steel beads, and the specific material accuracy is subject to the actual measurement. Note: the applicable size in the table is not absolute value, the specific material size is appropriate can consult the customer service. |

||

Package Demo

Dimensional Drawing

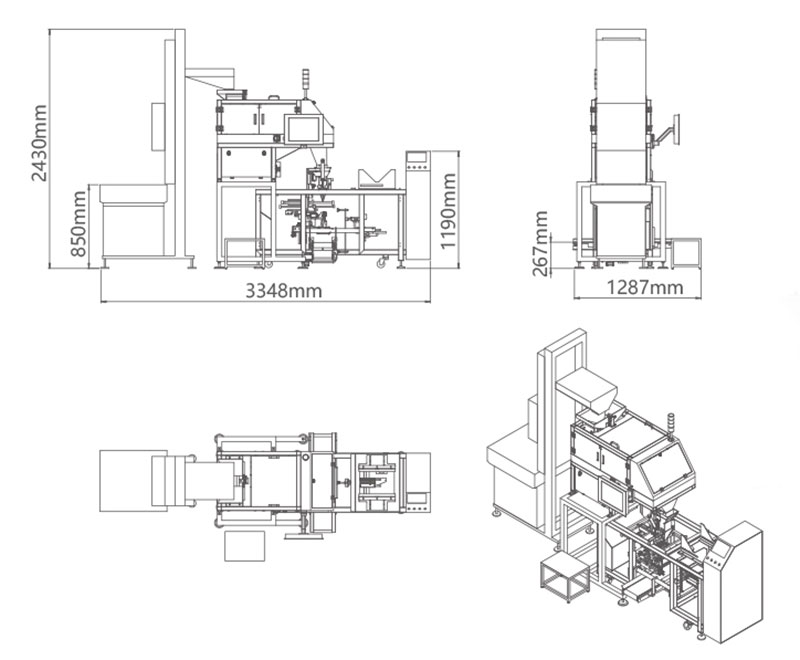

Customized lifting system + counting system + printing labeling system+ packaging system +product delivery

Available with multiposition bag packaging machine,vertical packaging machine,box/canned packaging line

VB+bag packaging machine

Video

Factory Show

Related Products