Multi-channel cabbage seed vision counting & packaging machine VF3

VF3 is 3-channel and high efficiency automatic counting machine which is suitable to different material, such as vegetable,fruit and flower seeds, fastener, food, capsule and so on. It is suitable for single package number 1000-5000pcs and more,it can work with different automatic packaging machine.

Working principle of cabbage seeds vision counting machine

High speed CCD camera scans objects that fall from vibrating chutes to obtain full projection images through optimized algorithm, machine will count number of falling objects so as to realize the batch package.

Technical data

|

Model

|

VF3

|

VF8

|

|

Applicable material size

|

Cube:2mm≤L≤30mm

Cuboid /cylinder:φ≤20mm,L≤50mm

|

Cube:2mm≤L≤20mm

Cuboid /cylinder:φ≤15mm,L≤30mm

|

|

Counting accuracy

|

99.99%,No negative error

|

|

Unit pack

|

≥100

|

|

Counting efficiency

|

Φ8mm,8000pcs,9bags/min

|

Φ8mm,8000pcs,24bags/min

|

|

Φ8mm,4500pcs,13bags/min

|

Φ8mm,4500pcs,35bags/min

|

|

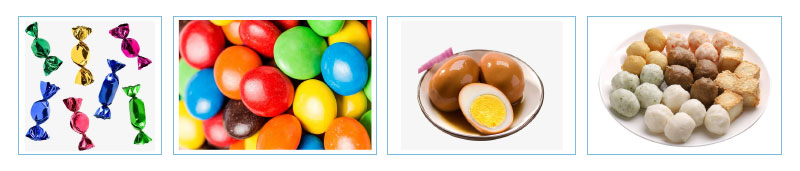

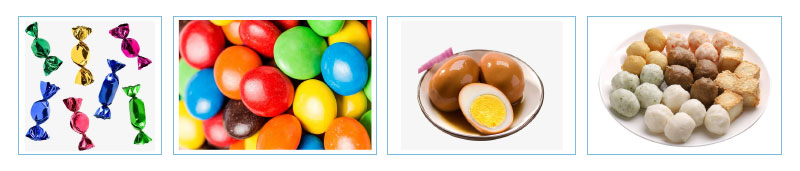

Type of applicable materials

|

Fasteners, connectors, cold pressure terminals, capacitor, zipper, buttons, seeds, medicine, blood collection needles, steel beads, etc

|

|

Applicable to packaging machine

|

Vertical and premade pouch packaging machine

|

|

Power/gas source

|

220V,50HZ/0.5-0.6MPa

|

|

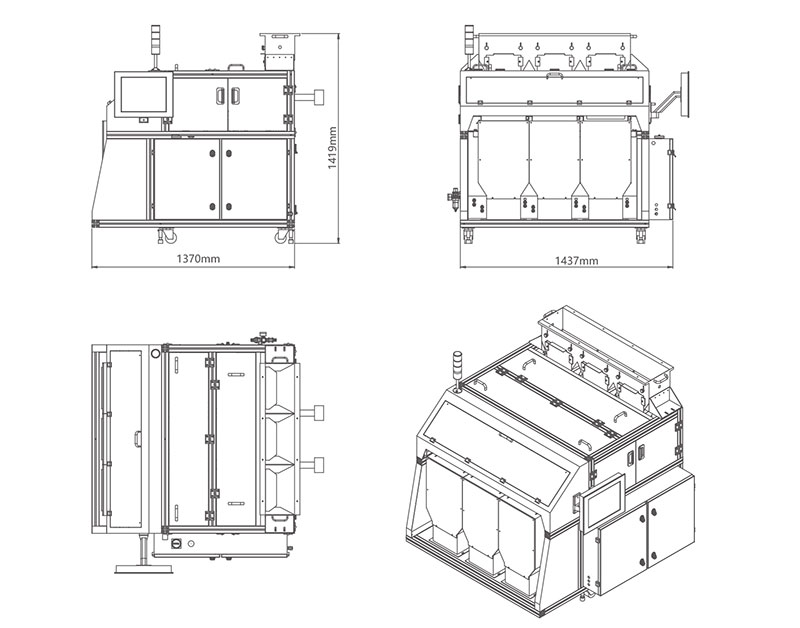

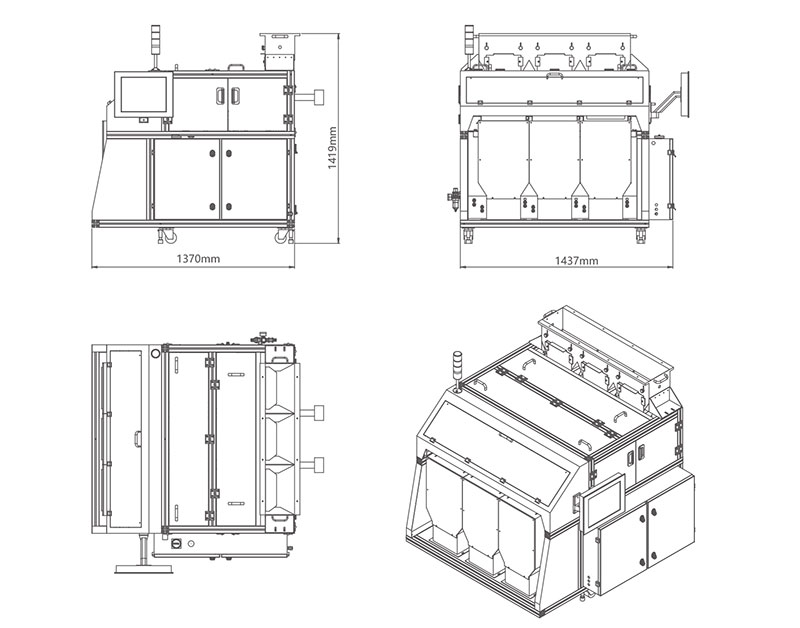

Dimension

|

1370mm*1437mm*1419mm

|

4933mm*3120mm*1419mm

|

|

Power

|

1.5KW

|

4KW

|

|

Note: The accuracy of 99.99% is based on the measured results of 5mm steel beads, and the specific material accuracy is subject to the actual measurement.

Note: the applicable size in the table is not absolute value, the specific material size is appropriate can consult the customer service.

|

Advantage of cabbage seed vision counting machine

-

Counting diameter range between 3 mm and 30mm

-

Precisely counts a pre-set number of seeds

-

User-friendly touch-panel operator console

-

High efficiency: Vision based counter uses large track and scan falling objects, instead of using several narrow tracks to separate objects one by one

-

99.99% accuracy for weight of each object is not exactly the same

-

Insensitive to dust

-

Fast changeover: One button operation for clearing to change objects

-

Self-learning software: Easy to calibrate for multiple objects counting

-

Extremely low maintenance

-

Reducing labor cost

-

Small footprint

Technical characteristics and Specification

-

Three-channel Large-output counting machine to meet the demand of Large-output counting counting and packaging

-

High frame rate CCD sensor, scanning frequency 10,000 times.It is equipped with 600W high-definition optical lens with minimum recognition size of 0.2mm

-

Advanced large-capacity FPGA processing and control system with response time of 1 nanosecond

-

Advanced software processing algorithm to effectively identify overlapping materials and micro-impurities in materials

-

Dual-channel and dual-temporary warehouse structure improves the counting efficiency to the greatest extent while increasing the counting

-

Industrial tablet computers, which can store a large number of production programs

-

One-button clearing button can shorten the clearing time and improve the production efficiency

-

Optional material return channel, for the over-standard package and tailings package does not enter the packaging link, effectively improve the accuracy of packaging products

-

Intelligent alarm function: alarm of material shortage, foreignbody detection, abnormal alarm of packing machine, alarm of exceeding standard

-

It has the learning function of exclusive patent, one-key learning for new materials and friendly man-machine interface,which greatly reduces the difficulty of operation

-

1t can be connected with ERP information of factories to achieve traceability of product production

Dimensional Drawing

Customized lifting system + counting system + printing labeling system+ packaging system +product delivery

Available with multiposition bag packaging machine,vertical packaging machine,box/canned packaging line

More field of application

Package Demo

Factory show

IPv6 network supported

IPv6 network supported