In the counting and packaging machine industry, most of the material counted are small materials of about a few centimeters. Small materials include terminals, hardware products, plastic parts, seeds, etc. Occasionally, large materials are counted, such as a hardware accessory material in the picture below, which is more than ten centimeters in length.

Look at the second material, not only the size is larger, the shape is also more three-dimensional. These are the typical large material count.

Counting such large materials is very difficult for traditional vision counting machines. Because of the size of the general counting machine, from the material input port to the vibration plate and the conveyor belt, including the size of the discharge port, it is difficult to meet the counting of such large materials.

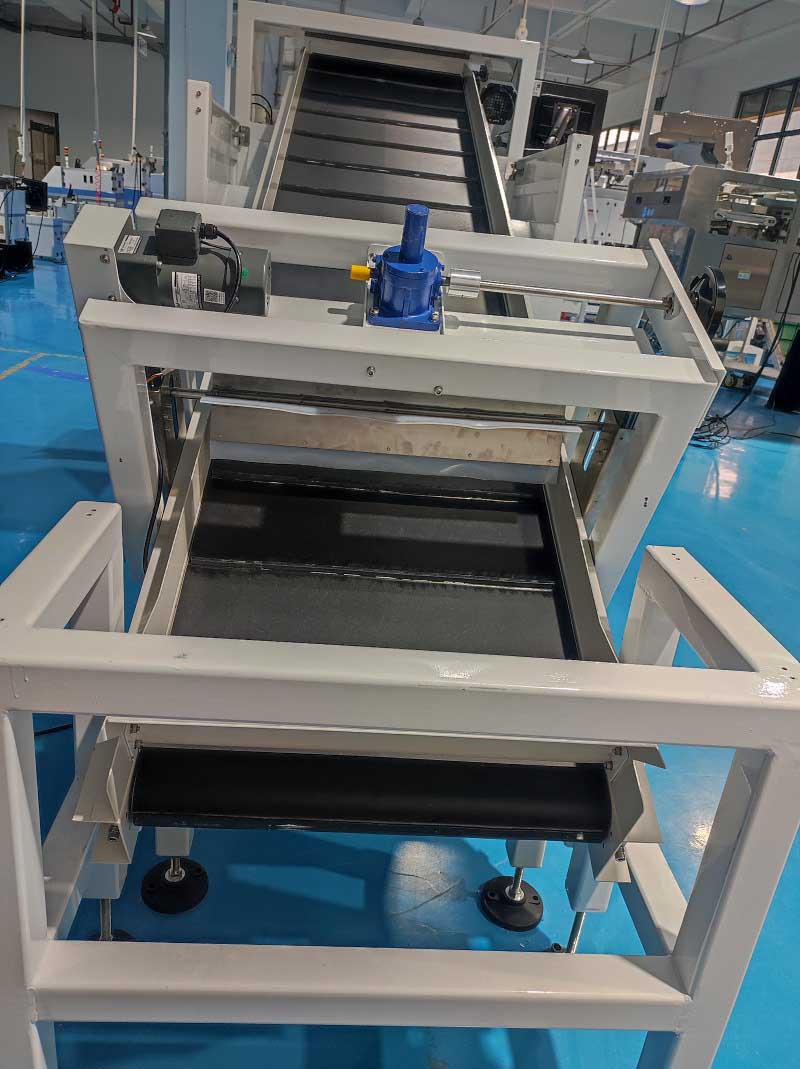

Therefore, when selecting a vision counting machine, an enlarged design must be carried out. This is the basic idea. Only when the entire equipment is enlarged can the requirements for quantitative counting be met.

Specifically, if the conveyor belt is widened on the material transmission, the width of the falling port of the counting machine should also be widened accordingly.

In this case, special consideration was given to not stacking the materials, so a rolling device was installed above the conveyor belt. The rolling sheets were made of silicone sheets to lay the stacked materials flat on the conveyor belt. In this way, the materials falling into the counting outlet can be even and the counting results can be more accurate.

Due to the use of climbing conveyor belt, considering the weight of the hardware material, to prevent the material rolling, the transmission belt must use the gold belt.

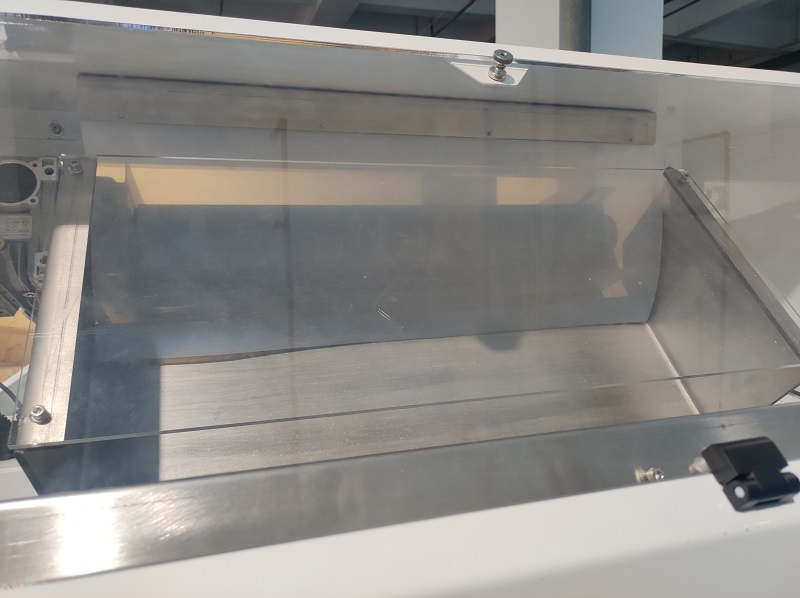

There are also details such as in the falling mouth to prevent large metal material from falling too fast, or may be thrown to the front of the counter acrylic cover, in the falling mouth of the added silicone material baffle.

The above measures are all designed for large materials or specific materials. The ultimate goal is to make the count more accurate in the normal operation of the packaging equipment.