How can vision counting machine better avoid damaging materials

In the field of automatic vision counting packaging machine, it will encounter relatively valuable or easily damaged materials, at this time, not only need to count accurately and quickly, but also especially to ensure that the material is not damaged during the counting process, which is a very difficult challenge for the counting and packaging process.

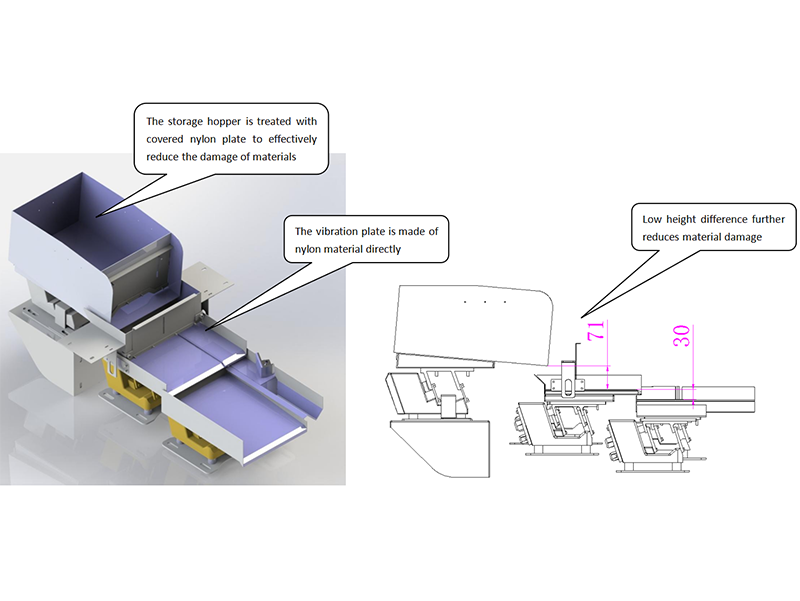

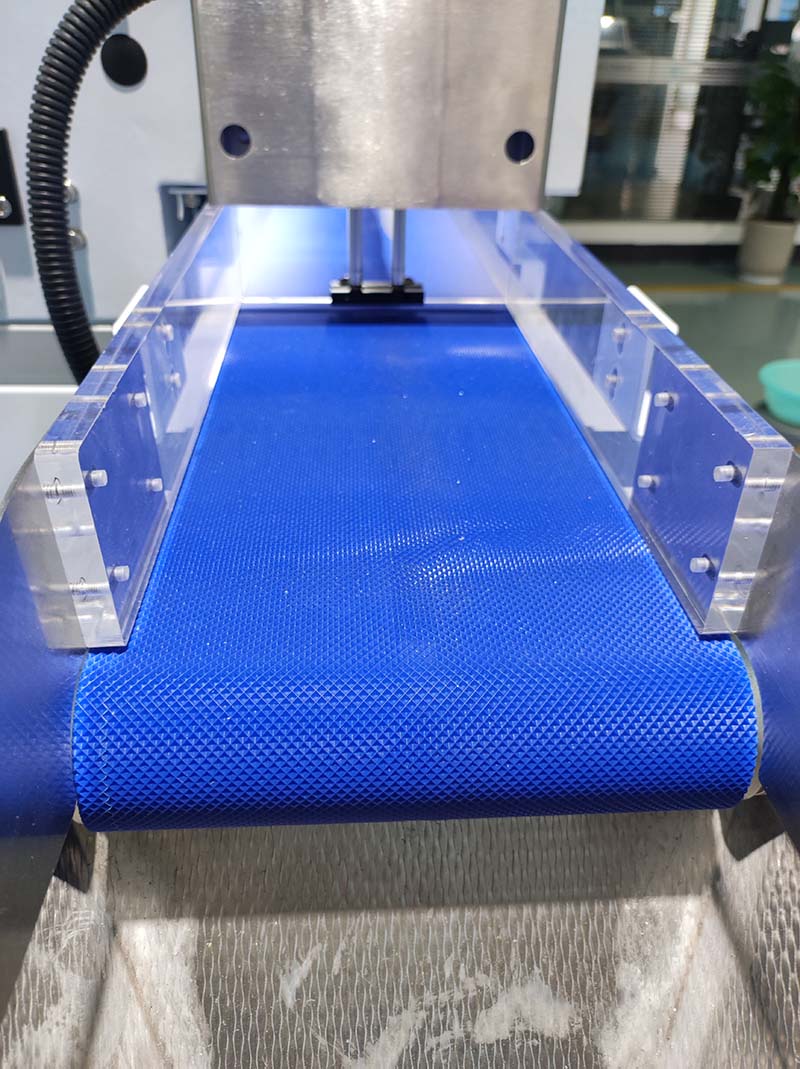

For this reason, professional design of material protection is required for this situation. Our low drop VBP series can meet these requirements. VBP low drop vision counting machine, when the material comes out of the discharge port, it does not fall directly into the container or packaging machine, but into a conveyor belt. The distance between the lower conveyor belt and the discharge port is relatively low, which reduces the collision of the material with the lower conveyor belt during the falling process. At the same time, because the conveyor belt itself is soft, it effectively avoids material damage.

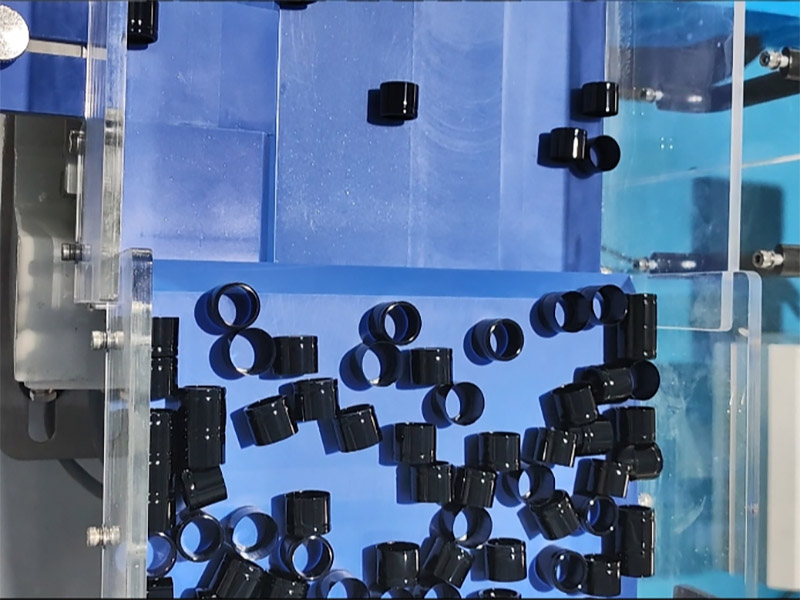

Take the following material as an example. This is a material sent by a manufacturer in the perfume industry. It is a black bottle cap accessory. The bottle cap has a glossy black paint surface, which can be easily scratched if not protected during counting. The perfume industry also has very high requirements for external packaging, and even the slightest scratch will not qualify. From the bottle cap entering the vibration hopper, and then entering to the vibration plate, and the baffle of the vibration plate, there may be slight scratches on the material, and this VBP is designed and developed to deal with similar materials.

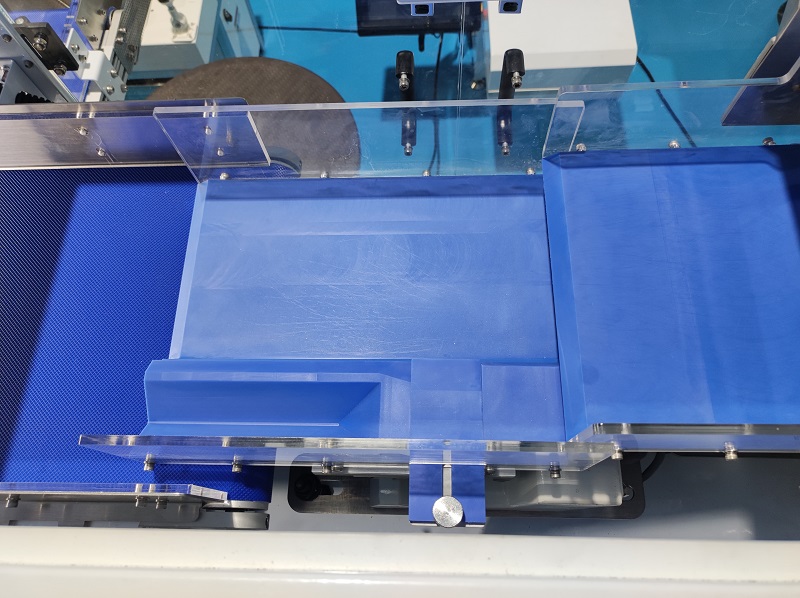

The vibration plate baffle of the VBP series is made of acrylic to prevent scratches on the material surface, and the bottom plate has also been specially treated.

And a section of conveyor belt at the front end can better protect the material surface.

In the actual count, the perfume bottle cap after repeated counting test, inspection, no surface scratches were found. After testing, the material is sent back to the customer, of course, the customer needs to carry out an acceptance inspection of the surface.

In the electronics industry, the counting of many precision electronic components must take into account the protection of materials, such as chip capacitors. In addition, such as ring gaskets, ceramic materials, magnetic disks and other counts are more suitable for using the VBP series for counting.

In the production process, in addition to the counting link to pay attention to the protection of materials, the feeding link, the packaging link, the material flow conveyor belt, etc., need to pay attention to the protection of materials. Only by taking all the steps of the material into consideration and taking measures to protect the material, can the pass rate of the product be increased to a greater extent.