Hardware parts counting and packaging machines for mixed hardware parts

Customer requirement: The main material are small hardware parts with 141-366 different types, the max parts are 5mm, majority material are small washers. Customer need pack mix parts in one bag, they have 55-64 unique hardware bags, each bags of parts are generally 6-8 types, up to 10 types.The maximum unique items in a bag are 16 (qty per varies)

For example some hardware bags they have are of 10 unique items

|

Material |

Quantity |

|

A |

3 |

|

B |

5 |

|

C |

2 |

|

D |

10 |

|

E |

9 |

|

F |

3 |

|

G |

1 |

|

H |

1 |

|

I |

4 |

|

J |

2 |

Bags size

|

Mill |

Size |

|

3 |

4x7 |

|

3 |

5x7 |

|

3 |

3x5 |

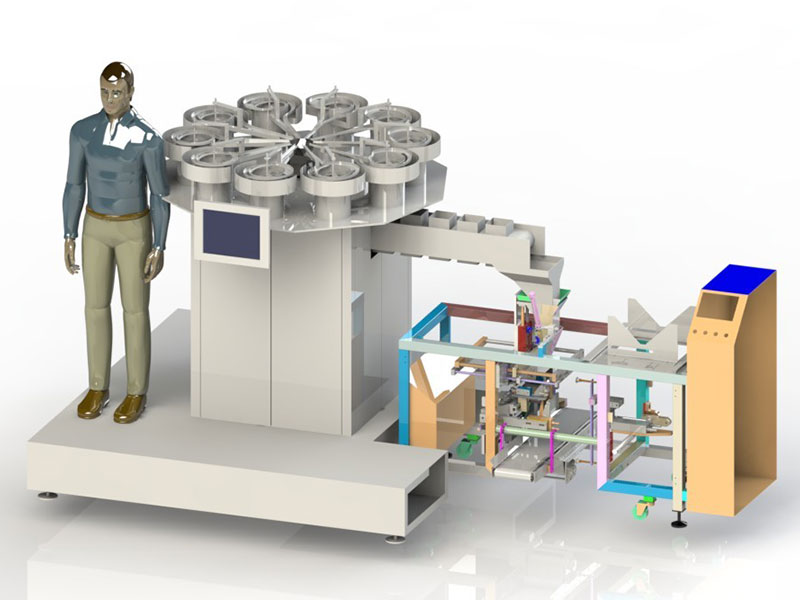

Adopt 10 vibrating plate feeding system +box conveyor + packaging system

1.Manual feeding: The operators shall pour the different hardware parts required to be counted into the vibrating plate storage hopper, for example, if you need count 6 different parts in one hardware bags, you only need use 6 storage hopper, if you need count 10 different parts in one hardware bags then you need use 10 storage hopper and so on.

2.Start counting: Click the counting button on the screen, choose the scheme(need to create by us or by yourself), and then will automatic counting, after counting, the first catching box will arrive in receiving port and collect the counted parts, then the second catching box will move forward and start collecting the parts and so on.

3.Bag packaging machine: When finished counting, the conveyor start work, the set distance of the box with the material moves forward, then catching box will flip and pour the counted parts on the packaging machine hopper, then packaging machine will start pack the seal the bags.

At present, customers use manual counting and packaging. This scheme can reduce labor and improve the efficiency,above all, this scheme can work with high accuracy. Here you can also get economic small parts counter.