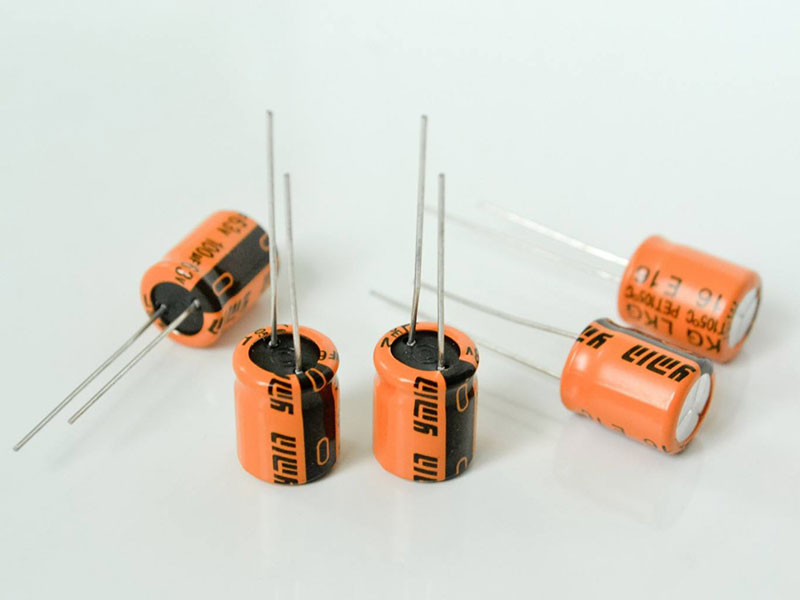

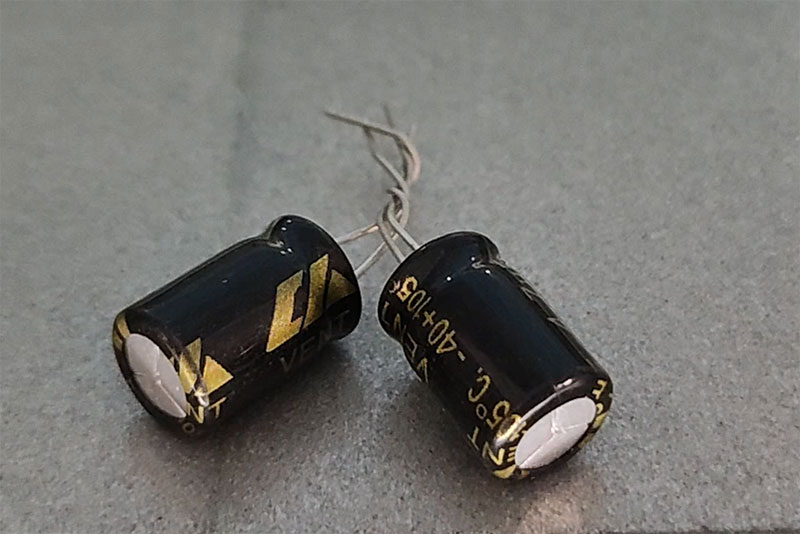

Application of Vision Counting Machine for Linear Capacitor

In the production of capacitors, the front end has to be cut, wound, cored and other production links, with a high degree of automation. However, the degree of automation in the subsequent packaging process is low, and manual weighing is mostly used. Since the production process determines the large difference in the weight of a single capacitor, the weighing method is used to count and package, which is prone to errors, which may be more or less. Therefore, in the actual packaging process, in order to prevent the shortage of materials, workers generally put more than a dozen materials after weighing each package to prevent customer complaints due to lack of materials.

Because the front-end process is mature and the quantity is large, so the packaging process consumes a lot of labor and wastes a lot of products. The packaging link is a shortcoming in the entire production process.After understanding our vision counting and packaging machine, some manufacturers require to install the equipment as soon as possible to solve the weak link of their counting and packaging to improve their overall production capacity.

Electronic component counting machine helps capacitor manufacturers to achieve full automation

Vision counting and packaging machine workflow

1. Manually pour the material into the leveling hopper

2. Scan the bill of materials with the material to obtain the scheme of the corresponding material (quantity of a single package and operating parameters) and label information. Print the label and stick on the bag

3. Click "Start Counting" to automatically count and drop into the prepared packaging bag. When the quantity in the bag reaches the set target value (single bag quantity), it will be automatically sealed and then dropped onto the finished product conveyor belt and transferred to the finished product collection area and collected by workers

4. If there is an over-standard package, the finished product conveyor belt will automatically reverse, and the material will be sent to the return area

Advantages of vision counting and packaging machine for linear capacitor

1.Count accurately, even if the material is cross together,can also be counted accurately

2.Will not be less material, reduce customer complaints, more material can be automatically recycled

3.Reduce manual input and restrict production efficiency

4.High packaging quality, improve product quality and corporate image

Videos